Design the part

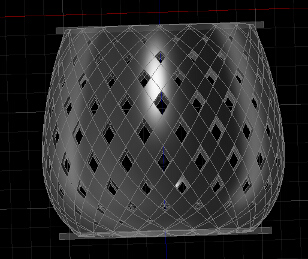

The assigment was to design and print a Model that couldn't be done subtractively. So I open Autodesk Fusion and design a Vase with a nice patern inside of it. I must say I was greatly inspired from what Mathieu did.

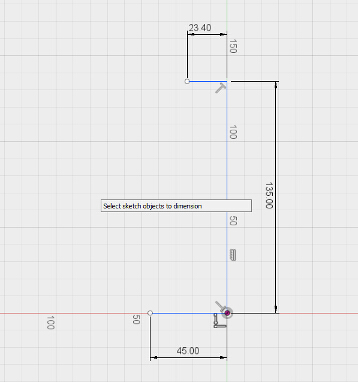

1st step:

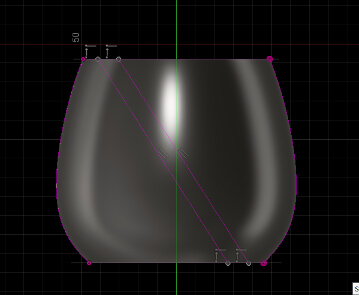

First I created a new sketch made of only 3 lines and set their dimensions:

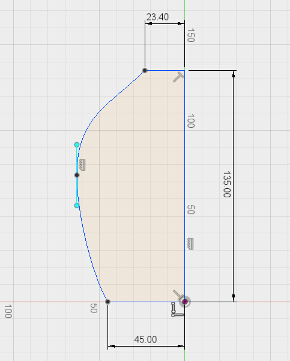

2st step:

Then I made a fourth line using the spline function:

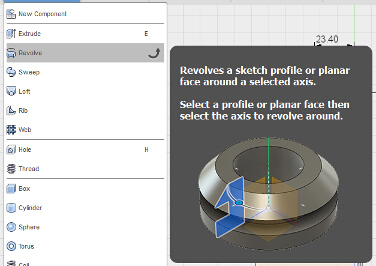

3st step:

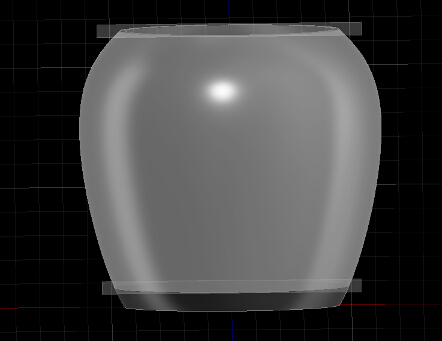

The I just had to use the revolution function to pass from a skect to a part.

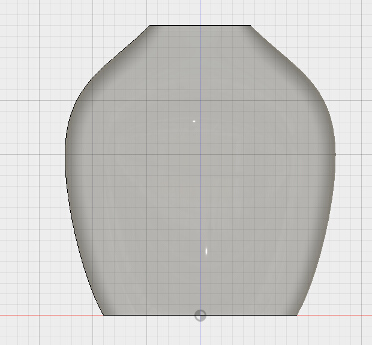

4st step:

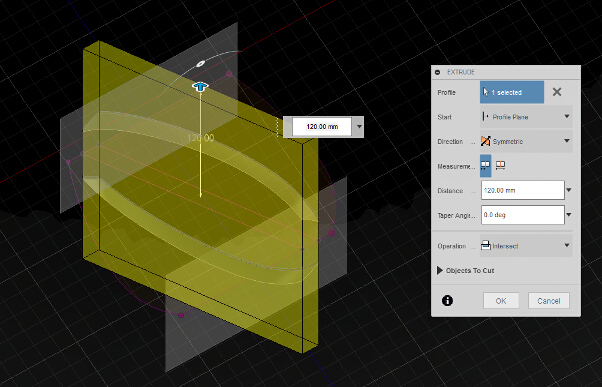

Now I had to divide my part in 3 bodies so I could keep the upper and down bodies intact while I applied my patern to my middle part. For that, I create a construction plane and set it where I wanted to divide my part, then I use the split bodies function.

5st step:

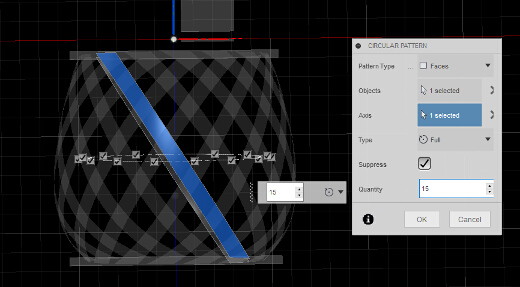

To create the pattern I used the project function for the sketch and then the circular patern to multiply the sketch 360 around the model. I dit it twice, once for each side of the two curve.

And here it is!

Fusion 360 being a cloud service, saves are stored in the cloud. Bizzarely, my file got lost and I try speaking with a Fusion technician, and he could'nt retrieve my file, he explained that i may have work on the design while being offline and the save got lost.....

Hope this will still be able to pass the evaluation...

« Go back to assigments page